| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : Fivemen

Model Number : LWS

Certification : ISO/CE/EAC

Place of Origin : China

MOQ : 1 set

Price : 10000USD-12000USD FOB China Port

Payment Terms : L/C, T/T, Western Union, MoneyGram

Supply Ability : 50 sets per month

Delivery Time : 45 days after deposite

Packaging Details : Wooden case

Function : liquid liquid solid separation for palm oil separation

MOC : 304SS or 316L/2205/Titanium

Bearing : FAG or SKF

Control : Siemens PLC touch screen with double converter

backdriver : VFD

Motor : double motor

application : Food grade olive oil

Electrical Element : Schneider, Taiwan DELTA, Siemens

Automatic 3 Phase Horizontal Palm Oil Decanter Centrifuge Separator For Oil Water Separation

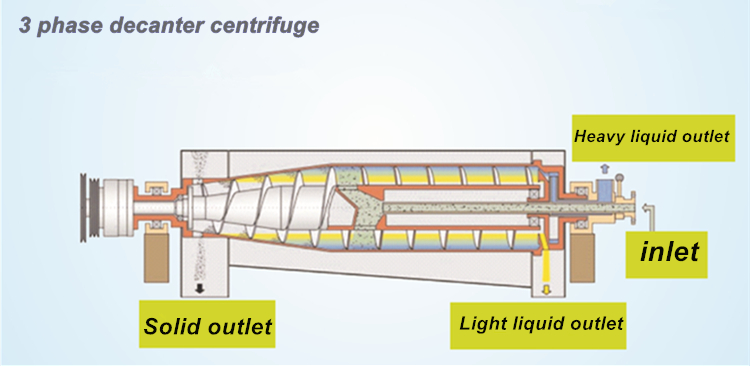

for the 3-phase tricanter,

The oil from the Decanter or Tricanter is then polished using a disc stack centrifuge, which separates the residual amount of water and solid impurities to obtain a clean oil.

The LWS decanter separator is suitable for plant oil,( such as palm oil, coconut oil, olive oil

separation ,) animal oil(such as fish oil, restaurant garbage ect) coal tar dehydration and slag,

adapted to the different viscosity and water content in coal tar separation (emulsion), after separating

the tar reach national standard.

Parameters :

2 phase Decanter Centrifuge:

| Type | Bowl diameter(mm) | Bowl length/ Bowl diameter | Bowl speed (r/min) | Main Power(Kw) |

| LW180 | 180 | 2.5-720 | 6000 | 3-5.5 |

| LW260 | 260 | 3.0-4 | 5000 | 7.5-11 |

| LW355 | 355 | 2-4.5 | 4000 | 11-30 |

| LW420 | 420 | 3-4.1 | 3600 | 18.5-37 |

| LW450 | 450 | 2-4.4 | 3600 | 18.5-37 |

| LW480 | 480 | 2-4.2 | 3200 | 18.5-45 |

| LW500 | 500 | 2-4.2 | 3200 | 18.5-55 |

| LW530 | 530 | 2-4 | 3200 | 22-55 |

| LW580 | 580 | 2-4 | 2800 | 30-55 |

| LW620 | 620 | 2-4 | 2800 | 37-110 |

| LW760 | 760 | 2-3.5 | 2500 | 55-132 |

| Note: In case of differences between the table and the user manual, the latter shall prevail. | ||||

3 phase Decanter Centrifuge:

| Type | Bowl diameter(mm) | Bowl length/ Bowl diameter | Bowl speed (r/min) | Main Power(KW) |

| LWS355 | 355 | 3.3-4.5 | 4000 | 15-18.5 |

| LWS420 | 420 | 4.1 | 3600 | 22 |

| LWS500 | 500 | 4.2 | 3000 | 30 |

| LWS530 | 500 | 4.2 | 3000 | 30 |

| LWS580 | 580 | 4.1 | 2800 | 45 |

| LWS620 | 620 | 4 | 2800 | 45 |

| Note: In case of differences between the table and the user manual, the latter shall prevail.

| ||||

2 phase Decanter Centrifuge:

3 phase Decanter Centrifuge:

When you need to separate solid / liquid mixtures with high solids content, you can choose a decanter centrifuge. In contrast to chamber filter presses, these solid vortex centrifuges or decanter centrifuges operate continuously. High centrifugal forces separate finely divided solid particles from the suspension.

Our decanter centrifuges are modular in design and can be used in a wide range of industries. Centrifuges can be optimally adjusted for specific applications. Applications range from all kinds of oil, waste oil, crude oil, vagetable oil, animal oil ect

Feature:

The decanter centrifuge can be adjusted to suit individual requirements by varying:

1.Differential with high precision, compact structure, smooth operation.

2.The part contacting with material is made of stainless steel.

3.Main bearing of imported bearings, to ensure the accuracy of the operation.

4.The machine system has two types, regular and explosion proof, to meet the different requirement.

5.The machine is equipped with a variety of safety overload protection devices, to make sure safety in production.

6.Large length to diameter ratio, high speed, many angels of drum cone structure

7.Spiral pusher surface adopts hard alloy materials, against abrasion powerfully

8.According to the customer's desire, the frame can develop to low center of gravity, high bracket and move.

9.Spiral structure with BD board is used for the concentration dehydration of activated sludge and difficult separate materials

Application:

1.Environmental protection city life of dirt, power plants, petrochemical refinery sludge sludge, coking, industrial sludge concentration, sludge dewatering.

2.Food and drink fruit juice slag, slag of animal oil, plant oil, soy protein isolates of dehydration, surimi, concentration of fish protein, wheat starch B dehydration.

3.Chemical * barium dehydration, kaolin industry classification and grade of graphite and PPT, classification of drilling mud.

4, oil separation, vegetable oil, like avocado oil, olive oil, sesame oil, soy oil and so on.

animal oil, pork oil, fish oil, chiecken oil, beef oil ect.

waste oil like the waste heavy oil, fuel oil, other waste oil.

5.Coal tar, coal tar dehydration and slag, adapted to the different viscosity and water (emulsion) of coal tar separation, after the separation of reach national standard tar.

Certification:

Main Parts

Photos

Applications

Packages

Our service:

Pre-Service

1. 24 hours onlinne consult and service

2. Introduce the details of products to the customers, answer the question raised by customer at firstly;

3. Providing the operation , installation and working video for customers.

4. Providing the different solutions for choice according to the needs and requirements of customers;

Sale Service

1. Ensure new product with high quality before delivery;

2. Packing according to the export requirements and shiping carefully;

3. Provide full set of documents as customer's requirements.

4. Providing one year sparing parts for you for free.

5. Delivery on time

After-sale Service

1. Help to install and debug the equipment, Our technicians could be dispatched for

overseas service.

2. Provide 24 hours techincal support by e-mail or phone;

3. Abundant spare parts in stock are available to provide.

4. Help customers slove any other questions about products or other aspect;

5. Your workers could get trained both in our factory and yours.

Service Commitment

1. We will provide 19 months warrantee to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.

2. Consultant services for whole machine life, 24 hours technical support by email and telephone.

3. Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

|

|

Double Motor Tricanter 316L 3 Phase Screw Decanter Centrifuge Images |